Walter Kind GmbH: Investing in Tough Times, Delivering in Every Cut

A Family Legacy That Shaped a Company

Walter Kind GmbH has been a family company since the late 19th century, and its history still shapes every decision made on the shop floor. “It was founded by my grandfather, Wilhelm Kind, in 1880,” recalls Walter Kind, Wilhelm’s grandson. The shop was just a small space on the main street of Beurisch, Germany, and it grew by serving canal boats and local customers.

Walter’s father, Johann, completed his master craftsman exam in 1926 and kept the business running. “In 1945 I was 15,” remembers Walter, “my father reopened and I became the first apprentice after the war.” He describes how the concept of generational responsibility and steady growth transformed the venture into the company it is today. He remembers expanding the premises, taking the difficult decisions to relocate and rebuild, and later founding a GmbH with his son in 1986. Moves that prepared the firm for larger industrial work and a broader customer base.

If you don't see them automatically, please activate the subtitles in your language.

Evolving Customer Demands and a Strategic Vision

When the company entered the 21st century, its customers began asking for larger, fully finished stair structures, balcony systems, and stage installations that required consistent edge quality, greater sheet sizes, and thicker cuts.

Gabriele Kind, who stepped into operational leadership after her husband’s, Walter’s son, passing in late 2024 and now runs the business alongside executive managers Karoline Schu and long-time employee Carsten Frank, says the move to a bigger laser was strategic. “The decision to purchase a larger laser cutting system came from our desire to focus more on the cutting and folding area,” she explains, adding that Walter Kind’s philosophy has always been to invest during hard times so the company can “come out stronger” when markets recover. Before the investment, the firm relied on plasma and a smaller 4 kW fiber laser, but these tools were increasingly limiting the company’s ability to deliver finished parts at competitive unit costs.

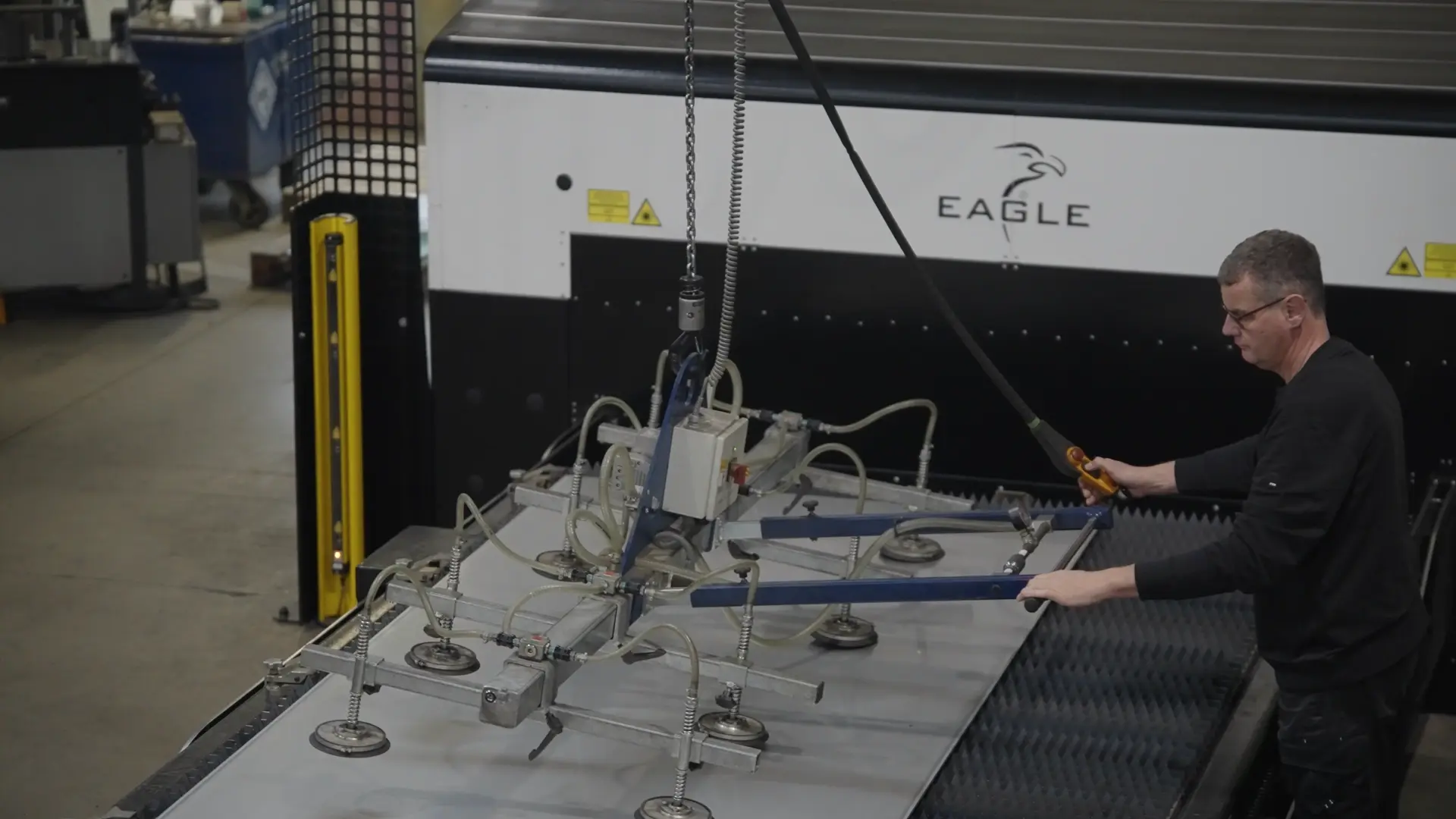

Production foreman Gert Lellig, who joined the company in 2008 and spends his days both planning and operating machines, remembers the practical limits: customers wanted large stair stringers and parts that forced the team to work on sheets bigger than the old table allowed. “We wanted a machine with a large table size and the power to cut thicker materials: something durable that would keep quality over time,” he says. The firm had used plasma since 2010 and knew the tradeoffs; switching to a larger fiber laser became the clear route to better efficiency and cleaner cuts on thicker material.

Choosing the Right Partner and Machine

After visits to trade fairs, on-site demos and test cuts at reference customers, and after comparing different machines, the team chose an Eagle eVision 10 kW 2040. Karsten Frank, who joined the managing team in 2024, describes the decision as practical and evidence-based. “Before acquiring the Eagle, we had a 4 kW fiber laser with a cutting area of 3 × 1.5 m,” he says, “it’s always fun to watch this new machine work, the power behind it, the speed, the precision, it’s impressive.”

Installation, training and the first months of production were focused on maintaining continuity: staff who already had laser experience picked up the new control logic quickly, training was comprehensive, and the vendor’s service visits were described as “uncomplicated, timely, competent.”

Gabriele noted that because the company had prior exposure to laser technology and because the onboarding was hands-on, “it wasn’t difficult for our staff to operate the new machine.” The practical benefits were immediate. Piercing and short-contour moves that once slowed down nested programs now execute so rapidly that whole jobs finish sooner; parts that previously required complex secondary processing now come off the table with edge quality the team can work with using existing deburring and grinding procedures.

Workflow Improvements and Expanding Capabilities

On the shop floor those improvements translated into steadier workflow and a visible change in scheduling. Where the team had once faced slow, fragmented runs and frequent manual interventions, the new setup delivers longer, more predictable production blocks. “We can work faster and handle larger quantities more efficiently,” Gabriele says, while Gert underlines the shift in capability: the company now cuts a wide range of materials: steel, stainless steel, aluminum, copper and brass, in thicknesses that go well beyond what the old equipment could manage. The added throughput has also meant that the grinding shop receives higher, more consistent volumes, which improves planning and reduces surprises.

“Delivery, installation and training on the machine by Eagle ran smoothly and on schedule,” Gabriele recalls, and the company has used the maintenance service twice with prompt and effective support. That reliability, together with the practical availability of consumables and spare parts, has reduced downtime and given the management confidence to plan for future investments rather than firefight day-to-day issues.

Karsten sums up the change in a way that links shop-floor pride to commercial reality: “The power, the speed, the precision are the factors that let the company quote competitively, deliver reliably and keep the familiar downstream finishing steps in place.”

The company’s roots and generational continuity remain central to how Walter Kind measures success. As Gert, Karsten and Gabriele agree, the machine didn’t change who they are; it simply made them more capable of doing for today’s customers what their founders began doing more than a century ago.