Van Kerkhof Metaalbewerking: Redefining Metalwork with Precision and Power

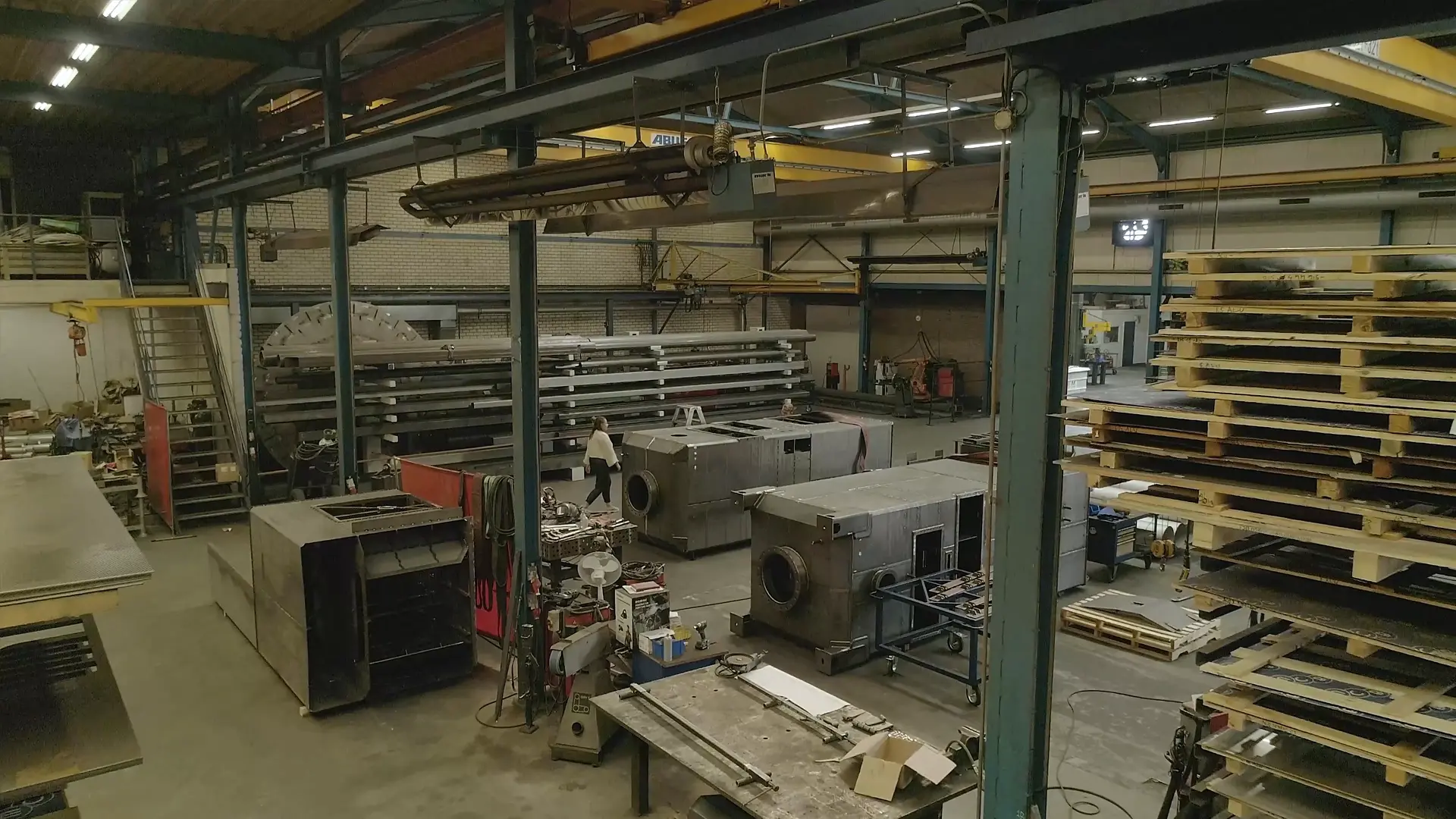

Located in Oss, a city in the southern Netherlands, Van Kerkhof Metaalbewerking is a company known for delivering high-quality metal products across diverse industries. Founded in 1977 by two brothers, the company began as a small business in the back of their family barn, tackling agricultural machinery and construction projects. Over the years, they transitioned into a full-scale metalworking powerhouse, with expertise in sheet, tubular, and box materials, creating semi-finished and finished metal components for diverse sectors. Today, Van Kerkhof specializes in complex orders for the agricultural and machine-building industries.

“Our first jobs were agricultural equipment and building structures—anything that could help us grow,” shares Leon Van Kerkhof, CEO and Co-Founder. “Now, we primarily provide precision-cut components and complex structures for agricultural machinery and machine builders. When it comes to sheet metal, we mainly cut a lot of steel, stainless steel, and also aluminum with thicknesses varying up to 50-60mm. Our reputation is built on delivering reliable, high-quality products that meet the rigorous demands of our customers.”

In 2021, they further extended their capabilities by investing in a tube laser. By combining this with their existing flatbed lasers, they were able to address a wider range of assignments and provide their clients with more comprehensive solutions.

From CO2 to Fiber: The Decision to Upgrade to an Eagle iNspire

As market demand increased and customer expectations rose, Van Kerkhof realized that their CO2 laser technology was no longer sufficient for meeting the industry’s evolving standards. Their team recognized that fiber laser technology provided a faster, more efficient solution and began evaluating options that would enable them to meet future market demands.

In 2022, they took a bold step forward by investing in Eagle’s iNspire 30kW fiber laser—a powerful machine designed for high precision, low downtime, and exceptional productivity. “The CO2 lasers simply couldn’t keep up,” explains Lenny Van Kerkhof. “With fiber, you get not only speed but also better results, even with thicker materials. We chose the 30kW Eagle iNspire for its cutting speed, reliability, and advanced engineering, like the polymer concrete frame and carbon fiber traverse, which make the machine incredibly stable and robust.”

A Purpose-Built System for Ultimate Efficiency

To maximize the iNspire’s potential, Van Kerkhof linked it to a warehouse tower with an automatic loading and unloading system, enabling seamless, automated sheet metal processing. “Efficiency is essential in our line of work, and this system allows us to load sheets, cut, and unload them automatically—productivity at its best,” she noted.

The 30kW Eagle iNspire’s cutting range of 4×2 meters provides Van Kerkhof with the versatility to handle both standard and heavy-duty projects. “With this machine, we’re now able to achieve very high cutting speeds and handle thicker materials with ease,” adds Lenny. The machine’s combination of speed and precision allows them to produce the same volume they once achieved with two CO2 lasers.

A Strong Partnership with Eagle and MML

Van Kerkhof’s relationship with Eagle began five years ago at a trade fair, where they witnessed Eagle’s capabilities through a live demonstration. “We were immediately impressed by the cutting speed and quality, and especially the machine’s solid construction,” says Peter Fleuren, C.O. “When we saw it in action and examined a cut piece ourselves, the decision was clear.”

In addition to the machine’s outstanding performance, Van Kerkhof has found Eagle’s support to be invaluable. “We have a great experience with Eagle and MML,” he shares. “Their team is incredibly knowledgeable, and their support has been reliable throughout. The machine installation went smoothly, and any minor issues during the startup phase were resolved quickly.” Van Kerkhof is confident that with continued optimization, they’ll be able to increase production even further.

An Intuitive and Operator-Friendly System

One of the iNspire’s standout features is its user-friendly interface, which allows operators to manage the machine with ease. “The machine interface is well-structured, and our operators became familiar with it very quickly,” notes Fleuren. “The learning curve was minimal, which meant that we could integrate it into our production line without delays. It’s as simple as loading a program, setting parameters, and hitting start.”

The Eagle has transformed Van Kerkhof’s operations, enabling them to take on more complex projects and improve delivery times without compromising quality. “Even though we’re not yet running at 100% capacity, I’m confident that when we do, we’ll exceed our previous production levels by a significant margin,” he adds.

Positioned for Growth and Innovation

As they look toward the future, the team remains focused on optimizing production and maintaining the flexibility that has always set them apart.

“The Eagle iNspire has been a fantastic addition to our operation,” says Leon Van Kerkhof. “We’re producing faster, with better quality, and less downtime. Our collaboration with Eagle has been a great experience, and we’re excited to see where this journey takes us next.”

With their commitment to high-quality work, innovative solutions, and strong customer relationships, Van Kerkhof Metaalbewerking is ready to tackle the challenges of tomorrow with confidence, ensuring their place as leaders in the ever-evolving field of metal processing.