Fiber laser technology for speed & innovation.

A global technological pioneer.

The multinational Swiss corporation ABB has joined the EagleTeam family. With 130 years of history and 110,000 employees in over 100 countries, the Zurich-based company is a global technology leader that continues pushing boundaries in the automation, robotics, and energy industries.Fiber laser for higher speed.

The ABB branch in Vaasa, Finland, manufactures 70,000 industrial electric motors annually. With such high production volumes, speed, efficiency, and automation are not only desirable but crucial.

ABB always keeps a broad vision and continuously explores new opportunities. Hence, as fiber laser technology grew in popularity within the market, they began to consider its benefits for motor manufacturing. They were crystal clear. Aside from efficient and speedy performances, fiber lasers require significantly lower energy, decreasing overall operating costs—a solution worth considering for electric steel cutting.

The switch to fiber laser technology was not a minor decision; thorough market research took place in the quest for the ideal machine. At the top of the list as equally important decisive factors were peak performance and service. ABB needed a device that, above all, would provide the highest possible productivity; the answer was Eagle. The iNspire 4kW, with 6G acceleration and ultrafast 9-second pallet changer, proved to be the right choice for their Finnish branch.

“We needed a high-speed device with very tough tolerance and accuracy. We realized that the Eagle iNspire was the fastest machine on the market” - adds Kalander.

Integration is Innovation

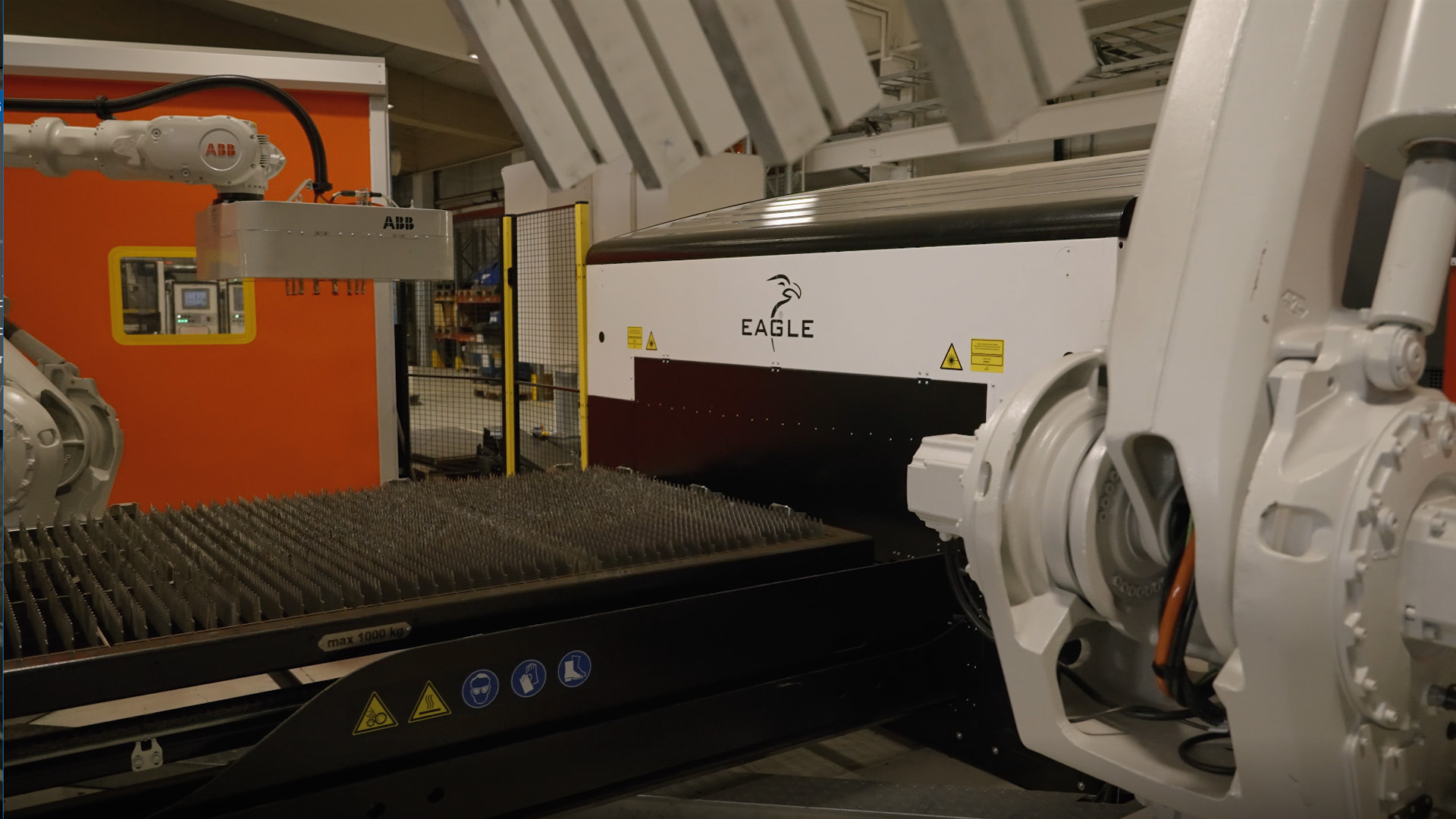

The iNspire laser cutter installed in the Vaasa plant is now integrated into a blanking machine and two robots to boost its efficiency.

The integration between Eagle’s machine and ABB’s robots came as a response to the corporation’s internal requirements for two technologies that could speak the same language to deliver a speedy and accurate joint operation.

How does this machine-robot collaboration work? First, one robot picks the material from the blanking machine and places it on the laser cutter’s pallet changer. Then, once the cutting process is completed, the second robot sorts out the material from the table and sets it on the unloading station.

Unsurprisingly, a pioneer in automation such as ABB would enhance their manufacturing processes with innovative solutions in robotics. Paired with the ultra-fast cutting by the iNspire, the Swiss manufacturer’s material-handling robots are, once again, raising the bar in terms of productivity.

Satisfaction guaranteed.

With its significant expertise and comprehensive portfolio of low-voltage motors, ABB's goal is to help its customers improve their processes' reliability, energy efficiency, and productivity. The same goes for Eagle’s fiber laser cutters, where every component is designed for the most efficient, precise and easy-to-operate production.

“Speaking of benefits, the most significant advantage of the Eagle cutter is the speed. It's the fastest machine I've ever experienced. What's also crucial is its absolute precision and repeatability. But I have to mention the interface. Operating it is so intuitive and straightforward that you feel like you are working on your iPhone. I could not be a happier customer than I am with the Eagle machine” - comments Kalander.

After this successful joint-venture we can’t help but think of the future. A next step could be to provide other companies with the advantages of this integration so that they, too, can benefit from ABB’s reliability and Eagle’s performance. Tomorrow holds endless possibilities.