Morgan Metal Corp: A Well-Earned Reputation in CNC cutting

Morgan Metal Corp takes us all the way south to sunny Brisbane, the capital of Queensland in Australia. The family-owned business was established in 1986 by Morgan father and son, and over the past 30 years has gained a reputation as one of the leading companies specializing in CNC cutting and stainless steel polishing.

“My father and I started doing architectural metalwork and stainless steel tanks, and then we developed into stainless steel sales and polishing of stainless steel products,” says Richard Morgan, owner and founder.

However, it was only in the 2000s that they ventured into the cutting process to be able to cut the plates they were polishing. They started out with a water jet cutter and five years later acquired a CO2 laser cutting machine. When fiber laser technology entered the market, Richard knew his company had to upgrade to stay ahead of the game.

“In the early days, the CO2's were competitive and they did make a nice cut, but then you started struggling on pricing against the new fibers that came in,” he told us. “With the way the technology advanced in those early years, we just held off as long as we could, because I always wanted to buy the best and the fastest.”

Hard Times, Good Decisions: The Quest for the Right Machine

Like many company owners on the lookout for the best-performing machine, Richard was researching several fiber laser manufacturers, Eagle among them:

“I was watching Eagle on YouTube and all the companies that were uploading reels on Eagle Lasers. Then I went to a show in Melbourne to watch the live demonstrations and it was everything I'd seen on YouTube.”

At the Melbourne exhibit, Morgan asked Kraftech (our distributor in Australia) for a quote without knowing what awaited in the months to come: COVID-19. As the pandemic hit hard, it shut down all businesses across the globe in what was probably one of the most uncertain moments for the manufacturing industry. Even so, Kraftech reached out to their potential customers to see if they were still interested, and Morgan had to make a major choice at a tough time. In the end, he decided to go for it and purchased an 8kW Eagle eVision.

“I think everyone was a little bit worried about investing that type of money and, thankfully, I did, and I haven't looked back since. The machine is definitely worth the investment, the cutting speed and reliability have been outstanding. After we purchased the first machine, we went from about five staff to 16 within the 3-year period and we keep getting bigger,” reflects Morgan.

The Second Eagle: A Paradigm Shifter

Morgan Metal’s new machine had brought such great benefits to the company in terms of cutting quality, speed, and turnaround times that they decided to purchase a second Eagle, this time a more powerful 15kW eVision which gave them room to divide the work depending on material thickness.

“We do all our thick plate on the 15 kW and all the sheet from 6 millimeters and below on the 8 kW. It was a big step, especially with the 15 kW, because we were the first company in Australia at the time to have such high power. It was a big decision but it’s paid dividends. You can't beat speed.”

On the usability aspect, Morgan also praises the ease of use of Eagle’s HMI and control panel: “You can learn how to operate the machine in around an hour. The tech tables are all set for you and it's pretty much: put your program in, hit start, and that's about it.”

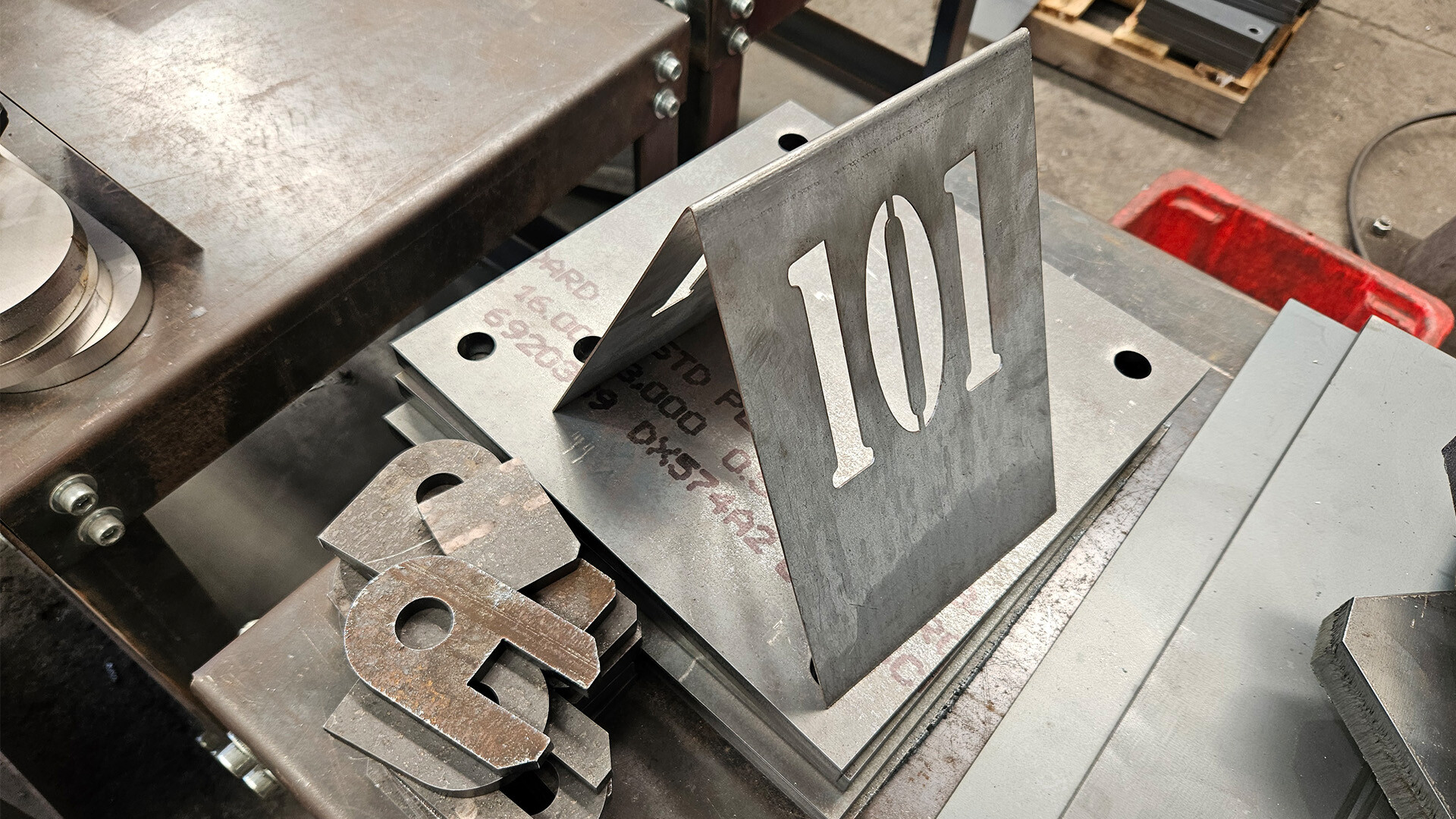

At present, Morgan Metal processes approximately 20 tons of material a day, most of it for the construction and food industries in the form of balustrading, handrails, conveyors, and others. They usually run on a 3-day turnaround from order reception to delivery.

Since the purchase of their Eagle fiber laser cutters, they’ve seen a yearly growth of around 20-25% and continue keeping their commitment to providing the best customer service possible through state-of-the-art equipment.

“I'd definitely recommend this machine to another customer in our line of work. Its reliability and speed are pretty hard to match, so on a competition basis, you'll be ahead of the game!”