Borderland Manufacturing: Doubling Capacity with Eagle Laser’s High-Powered Precision

Located in Manitoba, Canada, Borderland Manufacturing has grown significantly since its start in 2010. Initially equipped with a CO₂ laser, Borderland has expanded its production capabilities and now specializes in laser cutting, bending, sheet rolling, and welding for clients in the agricultural and architectural sectors. With a 2,000-square-meter facility and 20 employees, the company’s transformation gained momentum when it invested in an Eagle’s iNspire 20kW 2040 fiber laser.

“The Eagle laser has been transformative for us,” says Alex Hofer, Operations Manager at Borderland. “It allowed us to more than double our capacity while running around the clock with fewer staff.”

From Hours to Minutes: Production Transformation

“We found that our production was staying behind and we needed to upgrade”, tells Hofer. “We were looking for something that was going to increase our production and create the least amount of headaches for us, something that was solidly built and was gonna last us a long time.”

When they first came across advertisements for the Eagle laser, its high-power capabilities quickly drew their attention; it was unlike anything they had seen before. Up until that point, they had only used a 5-kilowatt CO₂ laser. After researching further, they found that a 20-kilowatt Eagle laser could replace two or even three CO₂ lasers, making the decision to invest in Eagle a straightforward one.

“We first heard about Eagle at Fabtech. We found online that it had a very good website, very knowledgeable. We liked that a lot. We could also email Eagle and send them test parts, and they would cut them and send us videos back. A very user-friendly experience”.

One of the most striking differences between CO₂ lasers and Eagle’s fiber laser technology is cutting speed. Borderland saw a staggering reduction in production time with the Eagle iNspire 2040. For example, cutting a 10mm steel sheet previously took up to two hours, but now it’s down to just 20 minutes. “The impact on timing and costs has been huge,” Hofer explains. “This speed has not only improved our efficiency but also helped us meet tight deadlines with ease.”

Automation and Increased Capacity

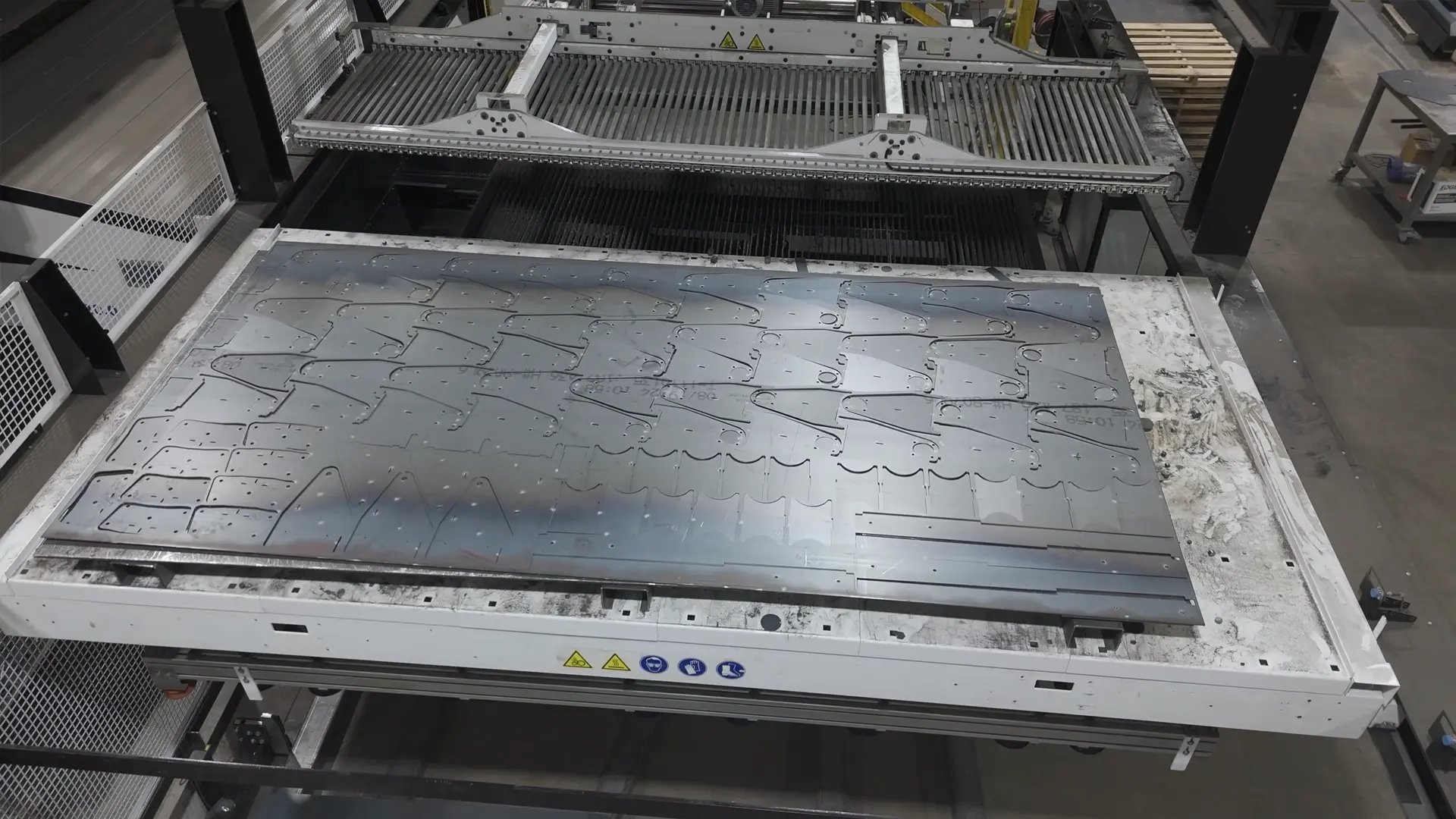

In addition to speed, the Eagle’s cutting head automation options, such as automatic centering and nozzle changing, have added efficiency and reliability to the production line. “The iNspire lets us work across different material types and thicknesses—from 1mm up to 40mm—without the delays and adjustments we faced before,” Hofer adds. “The movement speeds up to 6G and the MyEMIX technology were also big selling points for us. That was something that nobody offered at that time as well.”

To further optimize their productivity, Borderland incorporated Eagle’s CraneMaster, which has enabled continuous, 24-hour operation. “With the CraneMaster, we’ve gone from needing a full night shift to just one person on hand,” says Hofer. “This system keeps things moving smoothly and lets us meet high production targets with minimal supervision.”

Borderland’s operators appreciate the simplicity and durability of the CraneMaster. “We regularly load up to 25 sheets without a hitch. It’s a solid piece of equipment that’s helped us keep the laser running at peak efficiency,” Hofer notes.

Despite the high power of Eagle’s 20kW laser, its energy efficiency has been a pleasant surprise. “It uses about the same power as our old 5kW CO₂ laser,” Hoefer says. “We’ve seen huge savings on electricity and gas, which adds to the overall cost-effectiveness of the system.” This efficiency, combined with the Eagle’s speed, has significantly cut Borderland’s per-part production costs while boosting profitability across their projects.

Exceptional Support and Ease of Use

For Borderland, the move to Eagle was not only about technology but also about service and support. “The Eagle service has been exceptional from day one,” says Hofer. “Their MyESP program lets us send service requests directly from the machine, which means fast resolutions for any issues. Our team feels well-supported, and that level of reliability is invaluable.”

The Eagle’s ease of use has also been a significant benefit. “The layout is intuitive, and training new operators takes just a few hours. We’re used to different laser machines, but the Eagle is by far our favorite,” Hofer comments. This simplicity in operation has allowed Borderland to onboard new team members quickly and maintain high production levels without interruption.

A Path Forward with Eagle Technology

With its high-powered precision, energy efficiency, and reliable service, the Eagle laser has set a new standard for Borderland’s operations. “We’ve grown our production capacity and can take on more ambitious projects thanks to the Eagle laser,” says Hofer. “It’s more than a machine; it’s a partnership that’s reshaped our business.”

For companies looking to enhance production and profits, Hofer has one piece of advice: “I’d recommend Eagle to anyone serious about scaling up and improving efficiency. It’s made a significant impact on our business, and I’d choose it again in a heartbeat.”