Eagle is a global leader and producer of fiber laser metal cutting systems and automation solutions. We offer powers from 4kW to 30kW, and have 3 machine series to suit every production need. Our proprietary automation solutions seamlessly integrate with our cutting systems to provide customers worldwide with maximum efficiency, productivity, and reliability.

Our proprietary automation systems offer a complete solution for your business maximizing floor space and taking efficiency to the next level.

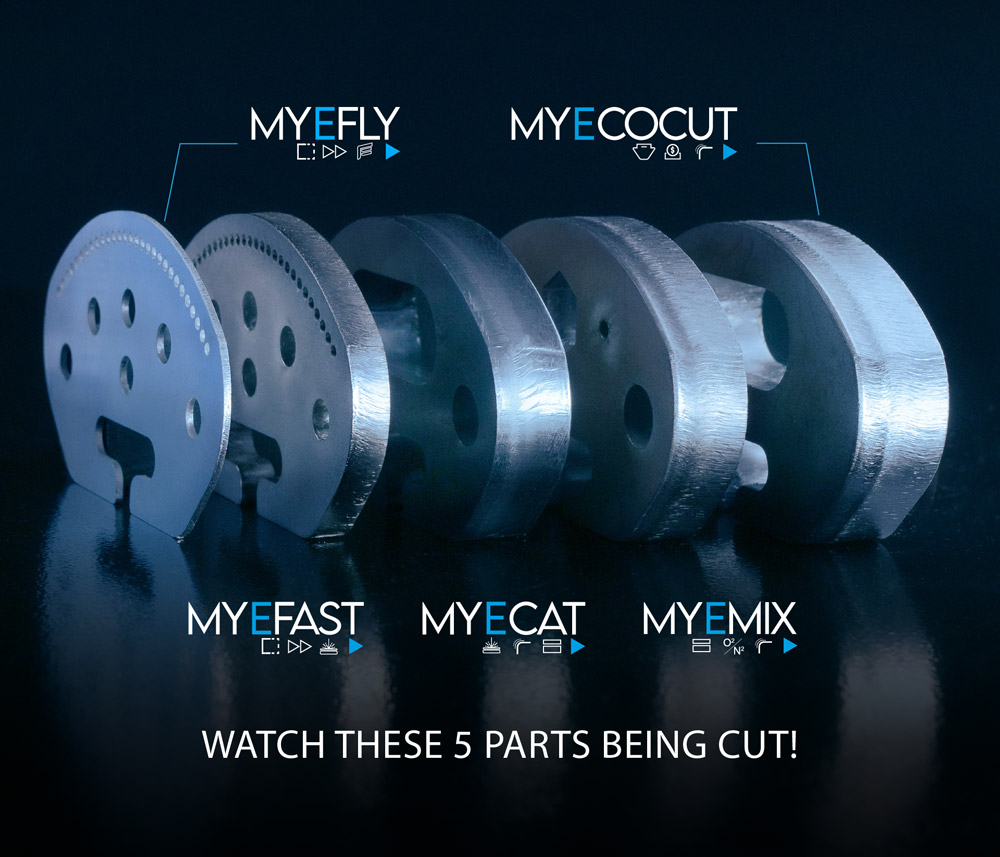

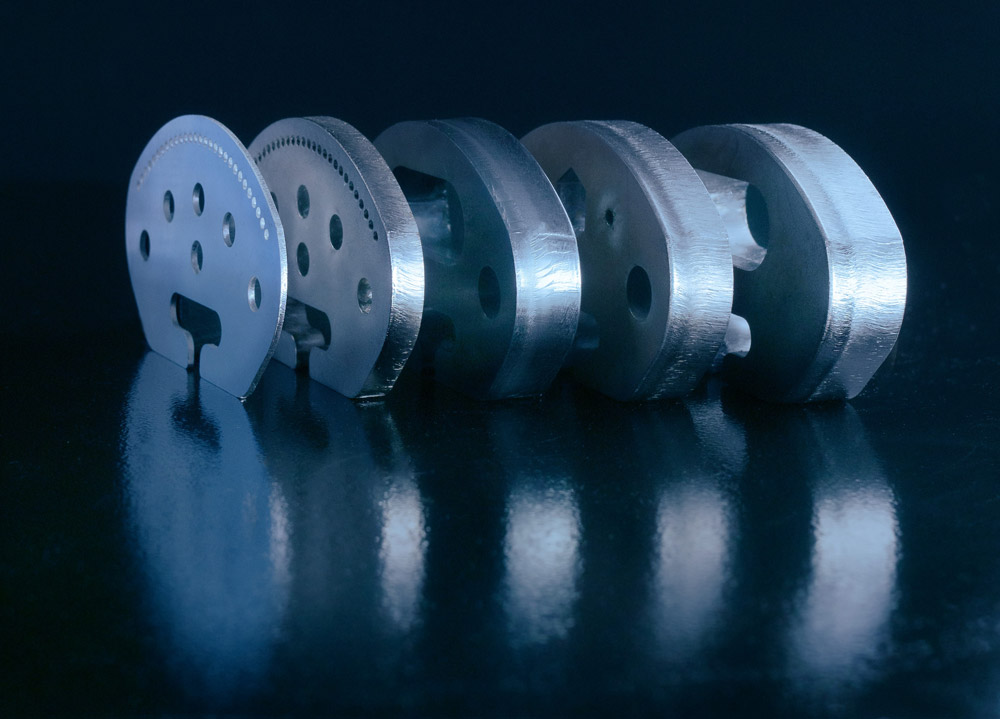

The High Five of Automation

Our technology is the product of careful research, tests, and trials to improve all aspects of the cutting process. We offer solutions that range from ultrafast cutting and piercing to a more efficient use of gas, from increased cutting capabilities for thicker materials to higher edge-quality. Our proprietary software and cutting tech covers all of our clients’ needs.

Designed to reduce part cycle time by piercing “on the fly”, keeping constant speed on thin sheets.

Designed to improve cutting and piercing efficiency on thin to medium sheets by up to 30%.

Reduces burr by 90% on thick materials and can cut 20% higher thicknesses with the same power. It improves piercing and small contour cutting and increases thick sheet throughput by up to 50%.

By automatically switching between oxygen, nitrogen and a mix of both, it reduces burr and increases edge quality on thick materials.

Reduces gas consumption by up to 75% while improving edge quality and maintaining maximum cutting speeds.